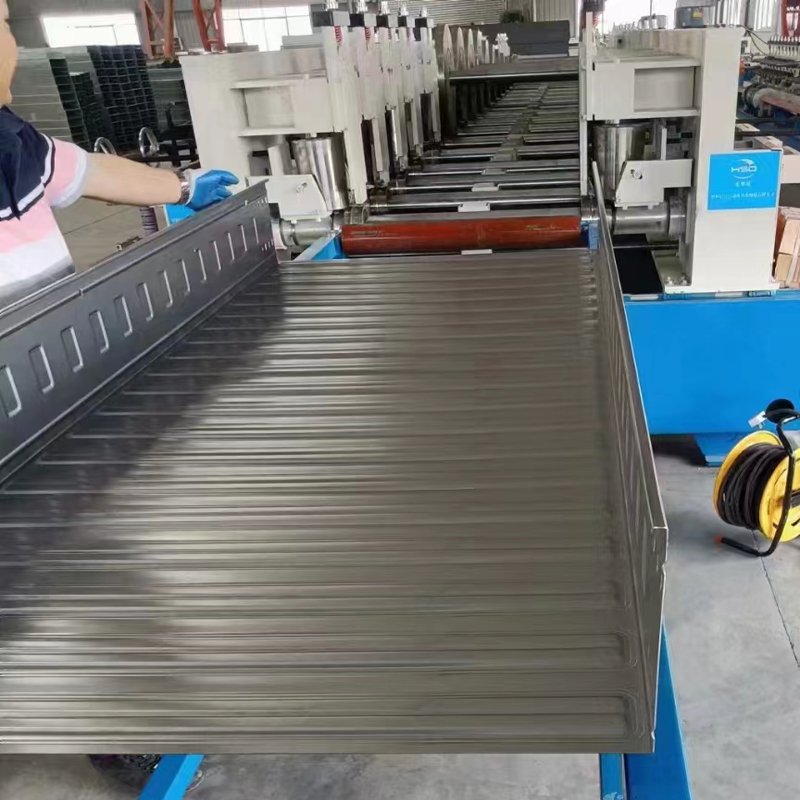

Cable Trunking Roll Forming Machine With Punch

This equipment consists of an uncoiler - a leveling feeder - a large-tonnage punch - a punching machine - a roll forming host. The uncoiler is a hydraulic core expander and is equipped with a pressing arm for easy operation. The leveling and feeding machine can accurately feed materials into the punch. , the punch machine can be used with large-tonnage molds to punch dense reinforcement ribs or dense pallet holes. The punching machine punches connecting holes, seven-character button holes, etc. All actions are controlled by the control panel. The roll forming host is composed of 35 axes, with a diameter of It is 80 mm, the surface is hard chrome plated, and the chrome plating thickness is 0.05 mm. Ensure the high efficiency, high precision and high flexibility of the production line.

Our manufacturing gear adopts superior automation science and is in a position to recognise a completely computerized manufacturing process. The gear is outfitted with superior electrical manage structures and mechanical transmission systems, which can recognise a couple of system steps such as computerized cutting, bending, and forming of cable trays. Automated manufacturing now not solely improves manufacturing efficiency, however additionally reduces labor depth and ensures the balance of product quality.

Secondly, our manufacturing gear is exceedingly adaptable and flexible. The gear can regulate more than a few parameters in accordance to product requirements, such as length, width, height, bending angle, etc. Therefore, whether you are producing cable trays of distinct specifications, or altering product patterns and models, our tools can meet your needs. This flexibility additionally affords clients with extra options and market competitiveness.

In addition, our manufacturing tools facets excessive precision and stability. The tools makes use of superior sensors and manipulate structures to reap specific manage of the size, form and attitude of the cable tray. The cable tray produced has the benefits of regular dimension and correct angle, which can correctly enhance building effectivity and set up quality.

Finally, our manufacturing tools is designed with security and reliability in mind. The tools is geared up with quite a number security safety devices, such as defensive covers, emergency end switches, etc., to make certain the security of operators. At the identical time, the gear adopts long lasting substances and structural plan to make sure the balance and lengthy lifestyles of the equipment.

To sum up, our manufacturing gear specializing in the manufacturing of small-sized cable trays has the benefits of excessive efficiency, precision, flexibility, excessive precision and stability. Whether it is in the fields of power, communications, transportation, etc., you can acquire exquisite cable trays thru our equipment, enhance work efficiency, minimize costs, and furnish sturdy assist for your projects.

Technical Parameters

Serial number | main component | Configuration | |

1 | Uncoiler | 1. Hydraulic core expansion 4. Distribution box (frequency conversion control, slow start and slow stop) 2. Electric discharge 5. Hydraulic 3KW set 3. Bearing capacity 12 tons | |

2 | Servo leveling feeder | 1、 Feeding code positive mechanism (positive and negative lead screw) 2、9 correction rollers, 4 up and 5 down 3、 4 feeding rollers, 2 up and 2 down 4、Servo feeding | |

3 | Pneumatic gantry punch | 1、Pneumatic gantry punch 2、1 set of combined grinding tools, mechanically molded 3、Bottom rib and side bulging molding 4、Pallet hole punching 5、Cut off 6、Shock absorbing pad 7、Mold transfer device | |

4 | Section A high-speed platform | 1、High-speed platform 6 meters (1 powered, 1 unpowered) 2、 Frequency conversion control 3、Positive and negative screw width adjustment | |

5 | Hydraulic punching | 1、 Connection hole punching 2、 Seven-character buckle stamping 3、 A set of hydraulic system 7.5KW+7.5KW 4、 Punching die: pneumatic switching of single and double row punches stamp | |

6 | Section B high-speed platform | 1、 High-speed platform 6 meters (1 powered, 1 unpowered) 2、 Frequency conversion control 3、Positive and negative screw width adjustment | |

7 | Roll forming part | 1、 Spindle φ80mm, surface hard chrome plated 5. Extended feeding guide 2、35 rows of forming rollers (single and double sides) 6. 1 set of flat surface straightening after forming 3、 The main machine is divided into 3 sections 7. Roll material: GCR15 4、 Long ribs on the side 8. Electric feeding | |

8 | Unloading rack | 1、2 passive unloading racks | |

9 | Control cabinet | 1、 The entire line adopts PLC control and touch screen human-machine interface to realize human-computer interaction. 2、Hardware configuration: Power distribution cabinet operation console, manual operation panel and wireless remote control next to the machine 3、 Operation mode: manual/automatic. In the manual state, it can operate as a stand-alone machine for easy maintenance; in the automatic state, it can operate across the entire line; it is equipped with an emergency stop button, making it easy to handle emergencies and ensuring the safety of equipment and operators | |