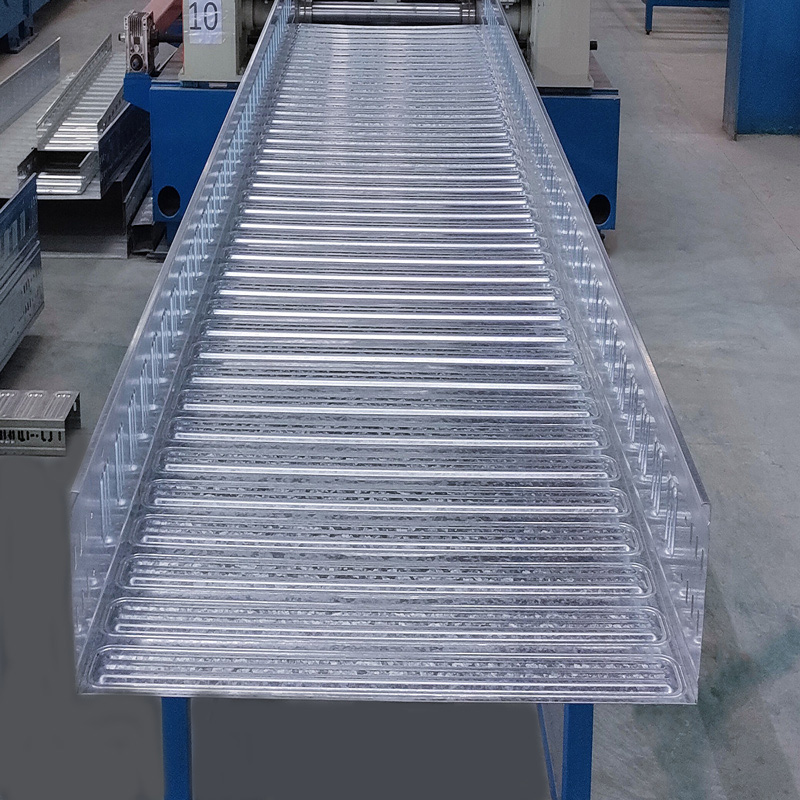

Cable Tray Roll Forming Line

The plates produced by this equipment are formed in one piece, using an integrated mold stamping manufacturing system. The unique one-piece rib material type has two R-grooves under the flange, which improves the load-bearing capacity of the flange and correctly prevents the cable tray from being unstable. In this way, thinner plates can be used, with higher load-bearing capacity, which plays a role in energy conservation and environmental protection! Products can be personalized according to your needs!

The unique one-piece rib material type has two R-grooves under the flange, which improves the load-bearing capacity of the flange and correctly prevents the cable tray from being unstable. In this way, thinner plates can be used, with higher load-bearing capacity, which plays a role in energy conservation and environmental protection! Products can be personalized according to your needs!

Serial number | main component | Configuration | |

1 | 1. Hydraulic core expansion 4. Distribution box (frequency conversion control, slow start and slow stop) 2. Electric discharge 5. Hydraulic 3KW set 3. Bearing capacity 12 tons | ||

2 | Servo leveling feeder | 1. Feeding code positive mechanism (positive and negative lead screw) 2. 9 correction rollers, 4 up and 5 down 3. 4 feeding rollers, 2 up and 2 down 4. Servo feeding | |

3 | Pneumatic gantry punch | 1. Pneumatic gantry punch 2. 1 set of combined grinding tools, mechanically molded 3. Bottom rib and side bulging molding 4. Pallet hole punching 5. Cut off 6. Shock absorbing pad 7. Mold transfer device | |

4 | Section A high-speed platform | 1、1. High-speed platform 6 meters (1 powered, 1 unpowered) 2、2. Frequency conversion control 3、Positive and negative screw width adjustment | |

5 | Hydraulic punching | 1、 Connection hole punching 2、 Seven-character buckle stamping 3、 A set of hydraulic system 7.5KW+7.5KW 4、 Punching die: pneumatic switching of single and double row punches stamp | |

6 | Section B high-speed platform | 1、1. High-speed platform 6 meters (1 powered, 1 unpowered) 2、2. Frequency conversion control 3、Positive and negative screw width adjustment | |

7 | Roll forming part | 1. Spindle φ80mm, surface hard chrome plated 5. Extended feeding guide 2. 35 rows of forming rollers (single and double sides) 6. 1 set of flat surface straightening after forming 3. The main machine is divided into 3 sections 7. Roll material: GCR15 4. Long ribs on the side 8. Electric feeding | |

8 | Unloading rack | 1、2 passive unloading racks | |

9 | Control cabinet | 1. The entire line adopts PLC control and touch screen human-machine interface to realize human-computer interaction. 2. Hardware configuration: Power distribution cabinet operation console, manual operation panel and wireless remote control next to the machine 3. Operation mode: manual/automatic. In the manual state, it can operate as a stand-alone machine for easy maintenance; in the automatic state, it can operate across the entire line; it is equipped with an emergency stop button, making it easy to handle emergencies and ensuring the safety of equipment and operators | |