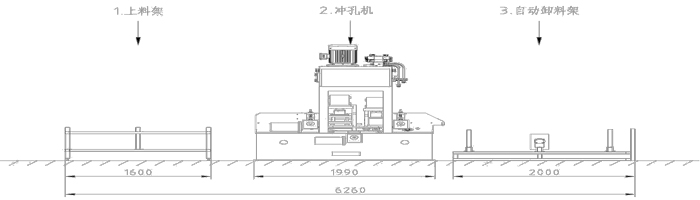

Cable Raceway Hole Punching Equipment

The Cable Tray Punching Machine is a specialized automatic equipment designed for efficiently punching holes (round, square, or custom shapes) in cable trays, metal raceways, and similar materials to meet electrical wiring, ventilation, and other installation requirements. Featuring hydraulic or CNC-driven operation, it ensures high precision, rapid processing, and interchangeable molds, making it ideal for mass production while significantly improving manufacturing efficiency and product consistency. Widely used in construction, power, and telecommunication industries, it serves as a key machine in cable tray production lines.

Mechanical Structure Composition

Frame: High-strength steel welding ensures punching stability.

Punching System: Hydraulic cylinder or servo motor drives the punch to provide precise pressure.

Mold Library: Supports quick mold changes to accommodate different hole patterns.

Feeding Mechanism: Automatic or manual feeding, combined with positioning sensors to ensure processing accuracy.

Control System: PLC or CNC control panel with programmable storage for multiple processing modes.

Working Principle

Positioning: The cable tray sheet is fed into the worktable via a conveyor and calibrated using optical or mechanical positioning.

Punching: The control system triggers the punching unit, and the mold completes the hole at the preset position.

Cycle: Automatic ejection and entry into the next processing stage enable continuous, high-efficiency production.

III. Key Features

High-Precision Processing

Uses CNC servo technology with positioning accuracy up to ±0.1mm, ensuring uniform hole spacing.

High-Efficiency Production

Punching frequency up to 60 strokes per minute, far exceeding traditional manual punching.

Flexible Adaptability

Quick mold replacement supports various hole types (e.g., φ10mm–100mm round holes, 30×60mm square holes).

High Automation Level

Optional automatic feeding and stacking systems reduce manual intervention.

Safe and Reliable

Equipped with photoelectric protection and emergency stop buttons, compliant with CE/OSHA safety standards.

IV. Technical Specifications (Example)

Specification 300~1500mm (customizable) | |

Max. Working Width | 300~1500mm (customizable) |

Material Thickness | 0.5~3.0mm (galvanized steel/stainless steel) |

Punching Accuracy | ±0.1mm |

Power Type | Hydraulic/Servo Motor |

Control System | PLC/CNC |

Power Supply | 380V/50Hz (3-phase) |

V. Applications

Construction: Batch punching of cable trays and bus ducts.

Power Industry: Sheet metal processing for distribution boxes and switch cabinets.

Telecommunications: 5G base station cabinets and cable runway production.

Transportation: Cable tray fabrication for subway tunnels and airport cable channels.

VI. Purchasing Guidelines

Production Volume: Choose manual/semi-automatic models for small batches and CNC automatic models for mass production.

Material Considerations: Harder materials (e.g., stainless steel) require higher punching force (25 tons or above).

Extended Functions: Confirm mold compatibility for special hole patterns.

VII. Maintenance & Care

Regularly lubricate rails and replace hydraulic oil.

Inspect mold wear and perform timely repairs or replacements.

Keep the working environment dry to prevent electrical system moisture damage.

Conclusion

The cable tray punching machine significantly enhances production efficiency and product quality through automated, high-precision processing. As smart manufacturing evolves, future models will trend toward higher integration (e.g., laser positioning + AI detection) to better meet industry demands